Features:

Equipped with safety protection that meets the requirements of enterprise safety management

Adopting intelligent temperature controller for precise temperature control, ensuring smooth and beautiful bag making

Adopting a three-stage roller type, longitudinal sealing, transverse sealing, and cold sealing to ensure the sealing effect

Equipped with a photoelectric tracking device, the bag length can be easily adjusted through a touch screen

Adjustable tearing device, sealing cooling device, high-speed cutting device

The machine can be equipped with different pump bodies for continuous or intermittent filling

The machine is equipped with a fault display system to help quickly handle faults

PLC program control function, parameters are set through human-machine interface touch, with counting function and product parameter storage function. The main components of the electrical appliances are selected from well-known domestic and foreign brands, which improves the stability, accuracy, and intelligence of the whole machine control

Optionaldevice:

Haiba pump;

Screw pump;

Rotali pump (CP pump);

Rotary pump;

Multi stage pump;

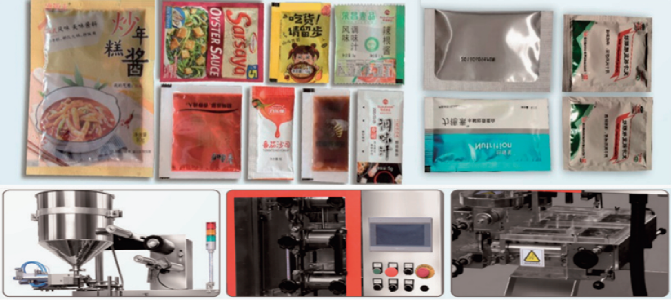

Scopeofapplication:

Viscous body, liquid, high-temperature liquid, soft particle fluid material

Technical parameters:

Packaging form: Three sided seal or four sided seal

Bag making length: 40mm-150mm (hot roller needs to be replaced when the length changes)

Bag width: 25mm-100mm (the molding machine needs to be replaced when the width changes)

Packaging capacity: 30-150 bags/min

Filling capacity: 0.5-80cc (actual packaging speed may vary depending on the characteristics of the raw materials, product size, packaging material, etc.)

Maximum roll diameter of film: 400mm

Gas consumption: 150L/min 05-0.8Mpa

Power supply and output: 3-phase 380V 5.5kw

Dimensions (with screw filling device): 900mm (L) x 1350mm (W) x 2200mm (H)

Host weight: approximately 550kg