Features:

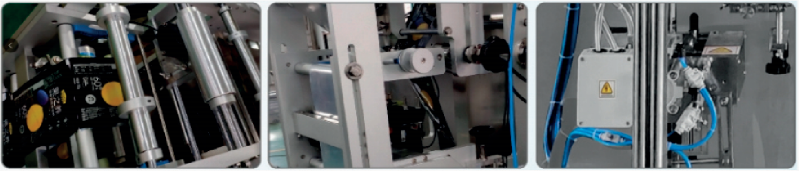

Equipped with safety protection that meets the requirements of enterprise safety management

Adopting an intelligent temperature control system, the temperature is automatically adjusted on the touch screen

Horizontal sealing film servo motor control

The bag length change and photoelectric tracking can be conveniently set through the touch screen

Adjustable tearing device, sealing cooling device, irregular cutting blade device

The machine is equipped with a fault display system to help quickly handle faults

PLC program control function, parameters are set through human-machine interface touch, with counting function and product parameter storage function. The main components of the electrical appliances are selected from well-known domestic and foreign brands, which improves the stability, accuracy, and intelligence of the whole machine control

Optionaldevice:

Measuring cup filling device

Disc vibration device

Skateboard device

Counting device

Multi head scale

Scopeofapplication:

Powder, granule, amorphous material, mixed material

Technical parameters:

Packaging form: Strip pack back seal, irregular strip pack back seal

Bag making length: 30mm-170mm (hot roller needs to be replaced when the length changes)

Bag width: 20mm-80mm (the molding machine needs to be replaced when the width changes)

Packaging capacity: 25-35 bags/minute

Filling capacity: 0.2-60cc (actual packaging speed may vary depending on the characteristics of the raw materials, product size, packaging material, etc.)

Maximum roll diameter of film: 400mm

Compressed air consumption: 300L/min 0.5-0.8Mpa

Power supply and output: 3-phase 380V3kw

Dimensions: 1400mm (L) * 950mm (W) * 2400mm (H)

Host weight: approximately 490kg